Room No: -1B02

Name of the lab in-charge:

Mr. Shahriar Raian

Assistant Professor

List of equipment:

Lab activities:

Yarn Manufacturing Lab is mainly designed for second-year students to final-year students. This lab is mainly used for conducting four sessional courses like Yarn Manufacturing I Lab, Yarn Manufacturing II Lab, Yarn Manufacturing III Lab, and Yarn Manufacturing IV Lab. In this lab, students are introduced to different types of machinery and their functions, material passage through them. At the very first of the Yarn Manufacturing I Lab, students are also introduced to layout diagrams and different mechanical parts for motion transfer such as gears and belts. Moreover, students are taught how to calculate different issues for example production, draft, and twist. Furthermore, the main goal of this lab is to provide detailed knowledge regarding the total yarn manufacturing process and production-related issues.

Room No: - 1B01

Name of the lab in-charge:

Mrs. Nasrin Akter

Associate Professor

List of major equipment:

Lab activities:

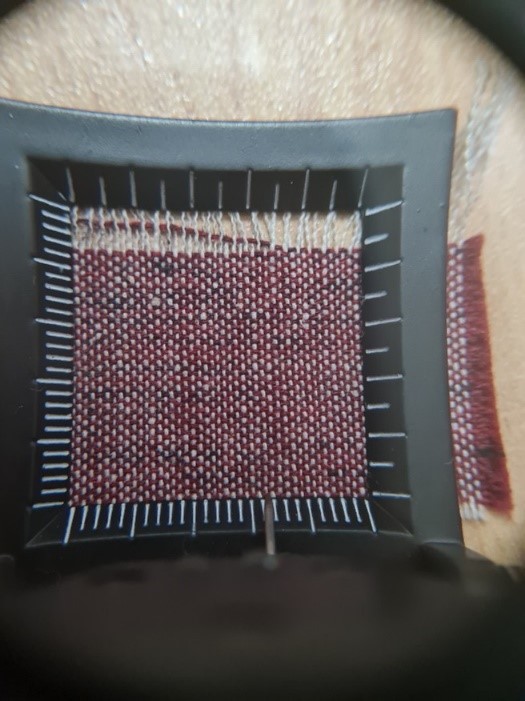

The fabric Manufacturing (Weaving) lab is well-equipped with winding machine, warping machine, sizing machine and different types of looms. In this lab, students can gain pragmatic knowledge about the fabric manufacturing process by using weaving technology. The focus of this lab is to introduce the students to the manufacturing techniques of woven fabric and the chronological development of loom with different shedding mechanisms. The students will be familiar with the core concept and theorems of weaving mechanism in the courses Tex-206 (Fabric Manufacturing-I lab, weaving), Tex-306 (Fabric manufacturing-II lab, weaving), Tex-406 (Fabric manufacturing –III lab, weaving), and Tex-426 (Fabric manufacturing –IV lab, weaving). In addition, the student can also apply their practical knowledge about weaving technology through their project work.

Room No: 6B03

Name of the lab in-charge:

Mr. Sheikh Nazmul Hoque

Assistant Professor

List of major equipment:

Lab activities:

Fabric Manufacturing Lab (Knitting) is furnished with some basic types of machinery and equipment for knitting. The students gain fundamental as well as advanced knowledge about knitting technology in this lab. Several sessional courses such as Fabric Manufacturing I Lab, Fabric Manufacturing II Lab, Fabric Manufacturing III Lab, and Fabric Manufacturing IV Lab are carried out here. The students also engage themselves in this lab for carrying out the experimental part of their project work. The machinery of this laboratory is used for manufacturing a wide variety of knitted fabric and several important fabric parameters are assessed by the equipment present in this lab.

Room No: 9B03

Name of the lab in-charge:

Mr. Md. Arif Mahmud

Assistant Professor

List of major equipment:

Lab activities:

Fabric Structure and Design Lab is used for analyzing woven and knitted fabrics. Analyzing fabric structure and design does not require many machines or resources, a handful of equipment is sufficient to serve the purpose. This lab is used mainly for the course titled Fabric Structure and Design Lab by the students of the third year first semester. The students of the final year of Fabric Manufacturing Stream also use this lab for analyzing various fabrics for Fabric Manufacturing-related courses and project work. The fabric structure and other specifications are analyzed using the counting glass and electric balance.

Room No: 6B01

Name of the lab in-charge:

Muksit Ahamed Chowdhury

Associate Professor

List of major equipment:

Lab activities:

Wet Processing Lab is especially designed and equipped for students of second year and onwards. This lab provides students with facilities to carry out different wet processing related experiments including pre-treatments, dyeing and printing, checking the purity of chemicals. The main object of this lab is to prepare students for taking challenges of the textile wet processing industry of the country by introducing them to different wet processing techniques, getting them acquainted with common equipment, chemicals and chemical measuring techniques.

Room No: 6B05

Name of the lab in-charge:

Mr. Mohammad Faizur Rahman

Associate Professor

List of major equipment:

Lab activities:

Most of the sessional classes related to apparel manufacturing are held in this lab. Apparel subjects are mainly taught in the second year, third year and fourth year. The experiments perform here include marker making, fabric spreading, fabric cutting, sewing, fusing, apparel washing & dyeing and so on. The lab also has arrangements for final year students to make the required sample apparel for their project works.

Room No: 6B07

Name of the lab in-charge:

Mr. Mohammad Faizur Rahman

Associate Professor

List of major equipment:

Lab activities:

This is the lab where students are taught how to cut clothes with a band knife. This lab also has the opportunity to test the fit after making apparel. Here the fit of the apparel is basically tested by some fit dummies. The lab has a very important role to play in the fit test of the samples made for the projects of the final year students.

Room No: 6B07

Name of the lab in-charge:

Mr. A.K.M. Mobarok Hossain

Associate Professor

List of major resources in the lab:

Total number of computers with an internet connection: 31

Operating system: Windows 7/XP

Available textile-oriented software:

Lab activities:

Computer laboratory of the Department of Textile Engineering provides different facilities to students to learn about different computer related theory and sessional courses including Application of Computer in Yarn Manufacturing, Application of Computer in Fabric Manufacturing, Application of Computer in Wet Processing, and Application of Computer in Apparel Manufacturing. Students are acquainted with different textile oriented as well as office-oriented software for the respective job fields.

Room No: 6B02

Name of the lab in-charge:

Md. Ershad Khan

Associate Professor

List of major equipment:

Fibre Testing Equipment

Yarn Testing Equipment

Fabric Testing Equipment

Colour Fastness Equipment

Miscellaneous Laboratory Equipment/ Items

Lab activities:

The Textile Testing and Quality Control Lab-1 houses the testing equipment of fibres, yarns, and fabrics. Moreover, various consumable items are used for testing of textiles. This lab is primarily designed to expose and introduce the undergraduate students to modern testing and analytical equipment and techniques. Besides sessional classes of several semesters, this lab plays a vital role for completing a significant number of Final Year Design Projects.

Room No: 6B03

Name of the lab in-charge:

Sonia Hossain

Assistant Professor

List of major equipment:

Lab activities:

This laboratory has been built to demonstrate and perform different basic and advanced experiments related to wet processing in different semesters. This lab is well equipped with different modern and sophisticated machinery required for color measurement, and recipe formulations as well as to evaluate the performance of the dyed samples. This laboratory also plays a key role for students to execute their final year design projects.